Which One Is Better—Laser Jewelry Welding or Traditional Traditional Soldering?

There are many ways to create jewelry, including different ways to connect metal parts. Two popular methods include laser jewelry welding and traditional welding. At Magic Cube Laser, we are confident that laser soldering is more beneficial due to several reasons. With good reason – polyamide. Let’s see why Laser Jewelry Welding Machine is the best choice for a wholesaler.

Laser Jewelry Soldering Is The Best Choice For A Wholesaler

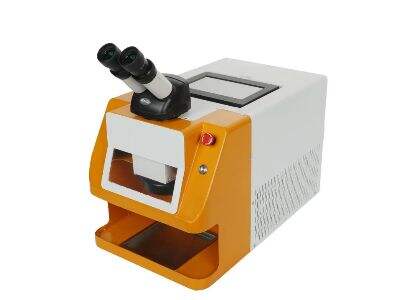

Imagine you are compiling jewelry in different metals. This is where laser technology will save a lot of time and effort! Laser soldering is a modern technique in which metal parts are connected by a light beam. One of the advantages of a Industrial welding machine is its impeccable precision. The laser beam is directed to the exact required amplitude, which ensures the tightness of the connection. When connecting, there are no flaws, and if necessary, you can do so accurately and evenly, so they need to connect complex models smoothly and flawlessly are used.

Laser Jewelry Welding vs. Traditional Soldering: Whats Better?

Another benefit is that the laser welding process is non-contact connecting. This means metal parts are not being soldered. They should not come into contact with the laser’s active part that is pointed. Therefore, you cannot do without such delicate processing, to break up or burn your expensive or rare workpieces. For Laser Marking Machine, too, this welder produces so little heat, the metal does not warp or change color.

Technology is an essential aspect of jewellery manufacturing.

In this regard, it would be appropriate to mention that laser technology is an integral part of the process to help manufacturers achieve their goals. First, laser technology allows for quick work. Laser welding is much faster and more efficient than soldering using hands and blow torches. In this regard, it is possible to state that laser technology is more suitable for accumulating production deadlines. Secondly, laser technology also allows for more design choices. Precision welding makes it easier to achieve most designs; this means that even complex designs or the smallest components can be fitted into a piece. This technological process is at the forefront in terms of precision and the ability to finely control the process. Moreover, laser welding is also a more environmentally friendly and a less messy procedure. These characteristics make laser welding a suitable process. In conclusion, laser welding is a better procedure than traditional soldering in terms of speed, precision, design choices, and environmental impact. Our company, Magic Cube Laser commits to offering high-quality jewellery manufacturing thanks to the innovative technologies in play.

To connect pieces of jewelry, two methods are commonly used – laser jewelry welding and traditional soldering. Laser jewelry welding implies melting the metal with a laser beam and connecting the pieces in the molten state. Traditional soldering, in turn, assumes fusing the respective metals in the molten state with the help of the heated metal alloy. Both of these methods have their advantages and disadvantages, although there is one optimal solution for your business. Below the difference is presented in the table. Laser jewelry welding has virtually all the benefits; it is more precise and does not require further polishing. One of the laser welding’s major advantages is its strength, and this method makes the materials practically monolithic. On the other hand, soldering is a classic process; it requires polishing and thus, more time.

Ultimately, if you strive to improve your work and speed up the welding process, the laser welding option seems to be optimal for your business. It is strong and relatively time-saving; thus, it is faster to complete many orders and hold deadlines. By obtaining the advanced technology for laser jewelry welding from Magic Cube Laser, it is possible to get ahead of your competitors radically.

FAQ: Can laser welding technology be applicable to the jewelry business and gems?

Which types of precious metals can be used with laser welding? The short response is that laser welding is only used with gold and silver. However, most of the other metals can also be laser welded with the proper equipment and configuration. How quickly can a jeweler learn how to use laser jewelry welding technology? It should be relatively easy for most jewelers to learn how to weld jewelry with a laser after receiving training and practicing. Laser welding has several advantages over the traditional method of soldering. As a result, purchasing laser welding equipment from Magic Cube laser might be an ideal choice for companies that wish to revolutionize their manufacturing processes and make new, remarkable pieces of jewelry.