×

×

Transform your production line with our precise and efficient CNC cutting machines. Ideal for complex parts manufacturing. Discover our range today!

The new favourite for manufacturing industries, which is the Magic Cube Laser precision cutting machine embodies the pursuit of extreme craftsmanship and perfect aesthetics. This laser cutting device has redefined what precision cutting means due to its outstanding accuracy and reliability. The Magic Cube Laser uses the latest technology in laser emission as well as a high –precision guide rail system to make sure that regardless of whether it may be a hard metals or delicate non-metallic materials it can be cut accurately up to micron level.

Moreover, this intelligent control system in Magic Cube Laser can automatically adjust laser power and cutting speed based on material’s thickness and type thereby increasing not only efficiency but also ensuring uniformity in quality of cut. For many industries, this user-friendly interface, strong compatibility will rest on making Magic Cube Laser an essential precision cutting tool that must always be there.

Magic Cube Laser’s precision cutters are rewriting the rules in industrial cutting with their unparalleled accuracy and excellent performance. It employs modern laser technology to make precise cuts at the micrometer level, working on metals, non-metals, and composites.

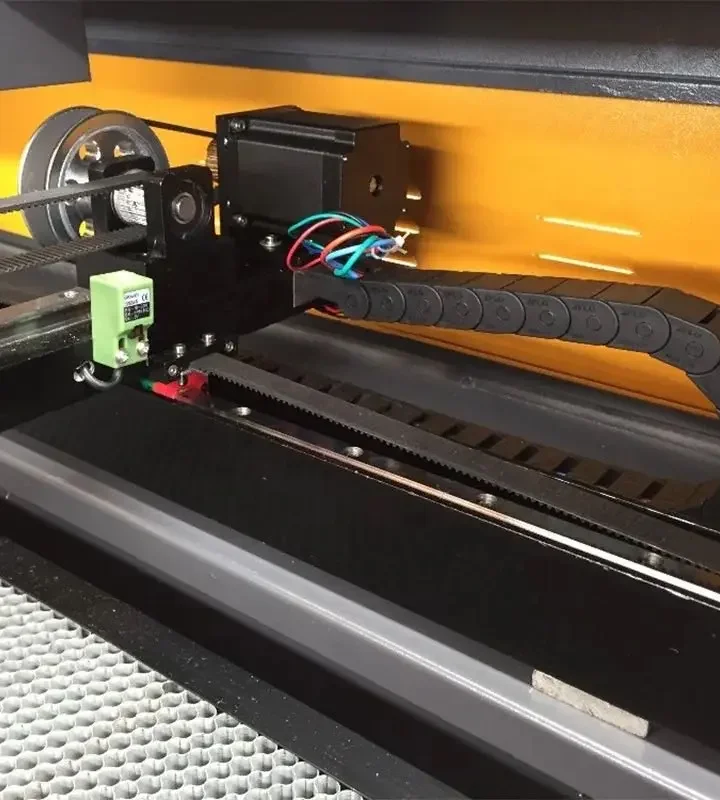

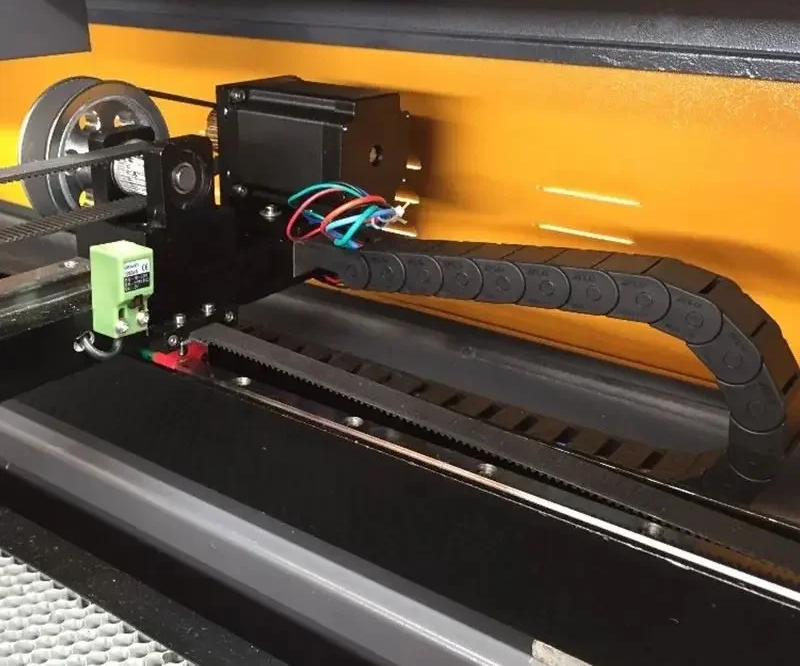

The Magic Cube Laser precision cutting machine is fitted with an automatic intelligent control system that allows quick and accurate cutting through set parameters, thereby enhancing production efficiency while minimizing human errors. Its integrated cooling system effectively prevents overheating and deformation of the workpiece so as to ensure high quality output.

With regard to functional versatility, this cutting machine can flexibly satisfy complex design needs; whether it is a micro-part or large sheets it can be done in one step with smooth edges without burrs. Furthermore, the appliance has remote monitoring as well as diagnostic features making maintenance easy and trouble shooting simpler.

This gadget enables a broad range of industries to find their way through production bottlenecks and upgrade to smart manufacturing.

Advanced optical recognition system is employed in Magic Cube Laser precision cutting machine which can automatically adjust to workpieces’ shapes and sizes for their smooth transformation from two-dimension into three-dimension space without any error in part cuts through dynamic focusing capabilities.

The machine guarantees that the heat affected zone in the cutting process is minimized and the overall quality of the workpiece is improved by using real-time temperature monitoring and closed-loop control strategy. It finds its use mainly in high-end manufacturing applications such as aviation or automotive where parts are required with precise geometrical features and uniform properties.

As industrial automation levels continued to improve, the conventional mechanical cutting processes can no longer meet the requirements of modern manufacturers for precision and productivity. The introduction of Magic Cube Laser is like a milestone for laser precision cutting technology. This laser cutting machine achieves accuracy down to the micrometer range in addition to boosting the cutting speed thus perfectly resolving the contradiction between production efficiency and product accuracy.

The Magic Cube Laser has a modular design that makes it easy to maintain and update, as well as support multiple laser source combinations hence applicable in different sectors. Its coming was not only made precise cuts possible for industries such as automotive, electronics, medical devices but also widened laser cutting technology uses in other areas.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our precision cutting machine can achieve a precision level of up to ±0.01mm, ensuring high-quality cuts for your materials.

Our machine is versatile and can handle a range of materials including metals, plastics, composites, and certain non-ferrous metals.

Yes, our machines are designed and manufactured in compliance with ISO standards and relevant industry regulations.

Yes, our machines are built for continuous operation with automatic cooling systems to prevent overheating.

The machine uses advanced servo motors and precision ball screws to control movement, along with feedback systems to monitor and adjust accuracy in real-time.

Cutting speeds vary according to the material, thickness, and complexity of the cut. However, our machines can achieve speeds up to several meters per minute.