×

×

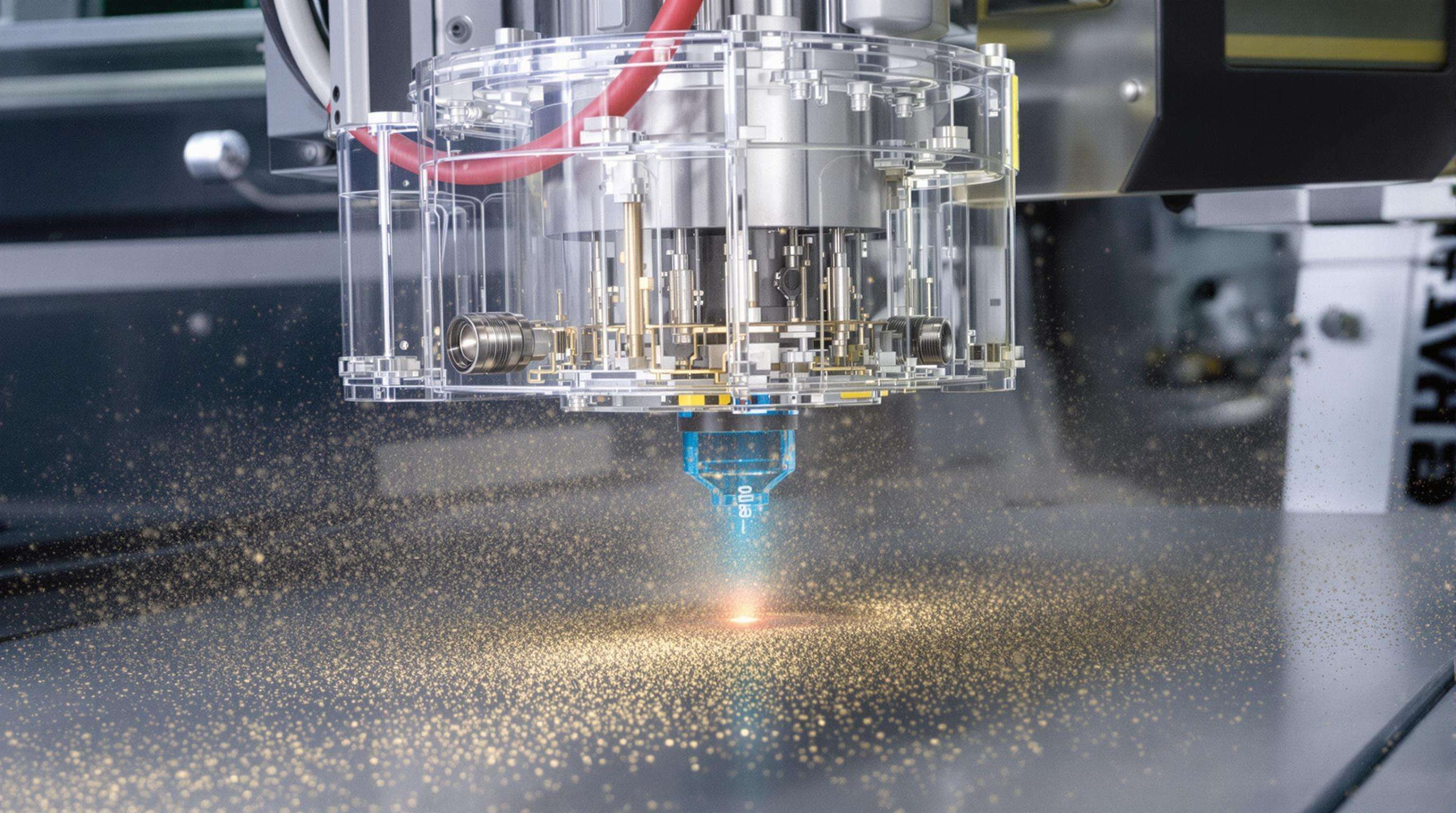

Fume filters act like the initial barrier stopping airborne stuff from messing with how accurately laser marking machines work. Tiny particles around 0.3 microns in size including things like metal oxides and bits left over from plastics tend to build up on important parts such as lenses and those galvanometer components. This buildup causes problems like cloudy lenses and beams that don't stay focused properly. According to research published last year, companies that installed HEPA quality filters saw about a 62 percent drop in needing to replace their optical parts when compared to places without any filtration at all. There's another issue too. When materials get vaporized during operation, these residues find their way into moving parts of the system. This creates extra friction in bearings sometimes going up as much as 27 percent according to findings from Ponemon Institute back in 2022. The increased friction leads to faster wear on machinery and ultimately means equipment doesn't last as long as it should.

| Contaminant Class | Source Material | Operational Impact |

|---|---|---|

| Metallic nanoparticles | Aluminum, stainless steel | Reflectivity loss on mirrors (≥15% over 500hrs) |

| Polymer fumes | ABS, polycarbonate | Deposits on focus lenses (– marking speed 22%) |

| Ceramic dust | Anodized coatings | Abrasive wear on nozzle components |

These contaminants degrade marking accuracy and force operators to increase laser power to compensate for beam attenuation, driving up energy use and consumable costs.

According to the latest industry data from 2023, facilities that switch to multi stage filtration systems tend to go about 40 percent longer between those pesky maintenance checks. Take one plant's experience over nine months where they tested hybrid HEPA and activated carbon filters. These filters kept capturing particles at nearly 99.97% efficiency for well over 1,200 hours straight, so production didn't have to stop for beam issues. And when plants start using smart filter monitoring through IoT technology, something interesting happens. They actually cut down on unexpected shutdowns by around 31%. How? The system warns operators when filters are getting close to saturation point, giving time to replace them before anything breaks down completely.

High-Efficiency Particulate Air (HEPA) and activated carbon filters play complementary roles in managing fumes from laser marking processes. HEPA filters capture 99.97% of particles ≥0.3 microns (EPA 2024), making them ideal for metal and ceramic applications. Activated carbon filters specialize in adsorbing organic vapors and odors generated during plastic or polymer processing.

| Filter Type | Best For | Efficiency | Maintenance Cycle |

|---|---|---|---|

| HEPA | Particulate-heavy operations | 99.97% @ 0.3μm | 6-9 months |

| Activated Carbon | VOC/chemical vapor removal | 95% organic compounds | 4-6 months |

A sequential HEPA and activated carbon configuration delivers measurable performance gains:

A 12-month study of 37 laser marking machines revealed that hybrid filtration systems:

Today's fume filters come equipped with load sensors that track how much dust builds up inside by looking at pressure differences and air flow rates. With this information, maintenance crews can swap out filters around 85 to 90 percent full instead of sticking to arbitrary time frames. According to a study from the International Manufacturing Technology Association back in 2023, this approach cuts down on early filter replacements by about a third. When these smart systems detect that limits have been hit, they send warnings to plant staff so they can schedule replacements during regular downtime periods rather than having to stop operations unexpectedly for emergency fixes.

Laser marking systems connected to the internet are starting to incorporate smart filters that send live performance updates to central monitoring screens. With this setup, plant managers can track how well filters work on different machines side by side, catching those that aren't performing right before they start affecting the quality of marks made. Looking at some recent studies from 2024, companies saw their problem solving time drop by nearly 30%, while saving around 18% on power bills thanks to better air flow management throughout the system.

Factories around the world are starting to test out AI systems that look at how filters have performed over time along with factors such as what materials they process and the power levels of their lasers. Companies that got in early saw about half as many unexpected breakdowns compared to before, since these smart systems actually place orders for new filters three days ahead of when problems are expected to happen. What's interesting is how this fits into the bigger picture of edge computing for industrial filters. When processing happens right on the device itself rather than sending everything to the cloud, predictions hit around 94 percent accuracy mark most of the time. Some newer models can even tweak filter settings as machines run, which according to preliminary tests cut down dangerous particles by roughly 40 percent in laser manufacturing setups where AI has been integrated so far.

Contaminants such as metallic nanoparticles, polymer fumes, and ceramic dust can degrade laser marking accuracy and efficiency.

HEPA filters capture 99.97% of particular matter like metal and ceramic particles, while activated carbon filters adsorb organic vapors during plastic processing.

Multi-stage filtration reduces filter clogging, extends filter life, and supports longer operating hours between filter changes.

Smart fume filters use sensors to monitor dust build-up, allowing filters to be changed timely before reaching saturation, reducing downtime.