×

×

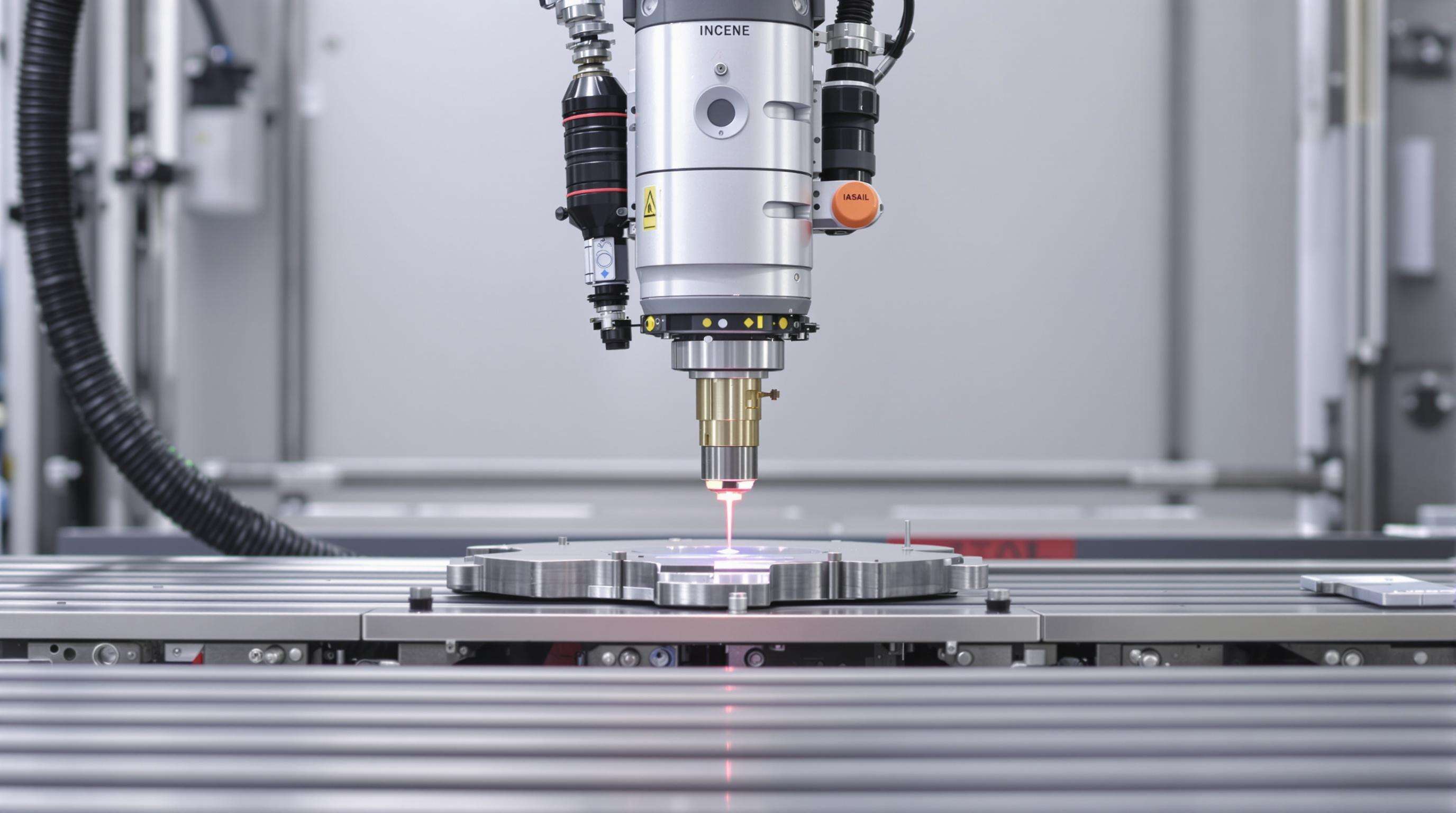

The connection between how fast laser markers operate and their energy needs isn't straightforward at all. When these machines first start running, they often draw around 2.5 kW according to recent reports from the Laser Systems industry in 2023. But once things settle down and the machine runs continuously at about 800 millimeters per second, it typically uses only 1.2 kW which is actually about a quarter less than what older engraving techniques consume. If operators need to slow things down to 300 mm/s for those really deep engravings though, energy consumption jumps by roughly 40%. That happens because the laser stays active longer on the material surface. Fortunately, newer equipment comes equipped with something called adaptive power scaling technology. Basically, the control system adjusts the amount of power going to the laser based on whatever speed setting has been programmed, helping keep overall energy usage efficient even when conditions change during production runs.

The latest fiber laser systems adjust their speed on the fly based on what the machine sees through its vision system. This means they don't waste power when moving around without actually marking anything, which cuts down on energy use during those inactive periods by about a quarter according to recent studies from 2024. There's also this clever feature called burst mode that switches back and forth between super fast pulses at 10,000 Hz when marking something and much slower ones at only 200 Hz when waiting. The system stays ready to go but doesn't guzzle electricity while sitting idle anymore, bringing the power draw down to just 300 watts instead of whatever it was before.

A tier-1 automotive supplier optimized CO₂ laser settings for valve spring markings, achieving significant energy savings while maintaining ISO/TS 16949 quality standards:

| Parameter | Original | Optimized |

|---|---|---|

| Speed | 650 mm/s | 900 mm/s |

| Pulse Frequency | 20 kHz | 15 kHz |

| Duty Cycle | 85% | 72% |

This adjustment reduced annual energy consumption from 58 MWh to 34.8 MWh. The 15-month ROI justified upgrading six legacy systems with adaptive frequency modulators.

Medical device manufacturers using UV lasers achieve 18% lower per-unit energy costs by applying variable speed profiles:

In contrast, the electronics sector reports 31% higher energy efficiency by combining speed presets with thermal load sensors. This prevents overheating during PCB marking while sustaining throughput of 1,200 boards/hour (2023 Semiconductor Manufacturing Report).

Laser marking technologies differ significantly in energy efficiency. CO2 lasers are the least efficient, consuming 7–15 kW with only 10–20% of input energy converted to usable output (Heatsign 2023). Fiber lasers outperform others, achieving 40–50% conversion efficiency at 2–4 kW. UV lasers, while essential for precision, require 15–30% more energy than fiber systems for delicate applications like medical device marking.

| Metric | CO2 Laser | Fiber Laser | UV Laser |

|-----------------------|-----------------|-----------------|------------------|

| Avg. Power Draw | 7-15 kW | 2-4 kW | 3-5 kW |

| Energy Conversion | 10-20% | 40-50% | 25-35% |

| Cooling Requirements | Active (High) | Passive | Active (Medium) |

Fiber lasers lead in efficiency due to three key advantages:

According to fiber laser efficiency studies, these systems deliver 40% lower operational costs than CO2 lasers in continuous production. Their direct diode pumping eliminates gas replenishment needs, reducing idle energy waste by 60–70% in batch workflows.

UV lasers (355 nm) consume 18–22% more power than fiber lasers when marking heat-sensitive polymers and semiconductors. This stems from energy-intensive frequency-tripling processes and active cooling requirements for optical components. Despite their importance in microelectronics (features <15 µm), UV systems average 35% lower energy efficiency in industrial benchmarks (2024 Laser Materials Processing Report).

Increasing marking speeds often raises energy consumption by 15–35% (Material Processing Journal 2023). For CO2 lasers, operating at 80% speed reduces daily throughput by 12% but cuts power demand by 22 kWh in continuous operations. The energy-speed relationship varies across technologies:

| Laser Type | Speed Increase | Energy Impact |

|---|---|---|

| Fiber | +25% | +18% |

| CO₂ | +20% | +30% |

| UV | +15% | +24% |

Modern controllers use real-time feedback to detect material hardness, automatically reducing speed by 40–60% when marking hardened steel versus aluminum. This prevents energy-intensive overmarking—a major source of waste, as fixed-speed settings previously accounted for 30% of industrial energy inefficiency on mixed-material lines.

Strange as it may seem, certain automotive facilities actually use 18 percent more energy when running their UV systems at full speed compared to plants operating around 85% capacity. Why? Because these high-speed operations need constant temperature adjustments and experience power spikes just to maintain accuracy at those extreme levels. Looking at actual industry data from last year reveals something interesting too. When one major manufacturer switched back to what they call "ideal" rather than maximum speeds for marking aerospace components, they ended up saving about 740 million watt hours each year. That kind of efficiency makes a real difference over time.

Neural networks now predict energy patterns 0.8 seconds before laser activation, adjusting pulse frequency and beam focus to maintain efficiency within 5% during speed transitions. Early adopters report 27% fewer energy spikes during batch processing compared to traditional PLCs.

Switching to pulsed laser operation cuts down on energy use somewhere between 22 and 35 percent when compared to running lasers continuously in those stop-start cycles according to research published in the Laser Tech Journal last year. The main idea here is simple enough really – turn the laser power on just when it needs to mark something instead of letting it sit idle drawing electricity all day long. Some recent findings from 2024 show how companies making parts for planes saved around 28% on their yearly energy bills after they started using these pulsed settings specifically for engraving serial numbers onto titanium parts. Makes sense when you think about it since titanium requires pretty intense processing conditions anyway.

Regenerative circuits recover up to 18% of unused energy during pulse intervals. In high-speed fiber laser systems, this energy is redirected to auxiliary systems like cooling units or positioning motors. Field tests show these circuits save 9.7 kWh/day in 24/7 automotive operations without compromising speed or quality.

Laser systems today can save anywhere from 15 to 30 percent on energy bills simply because they adjust their speed while running batches. The trick lies in something called pulse frequency modulation, which actually cuts down on wasted power by around 22% according to some recent research (Ponemon Institute, 2023). When these lasers switch back and forth between fast engraving mode and their sleepy standby state, they don't just sit there drawing unnecessary electricity anymore. A real world case comes from one chip maker who managed to slash their yearly power expenses by nearly $18k after installing smart speed control systems. These new protocols basically make sure the lasers only fire up when needed, matching their activity perfectly with how the production line moves along.

| Metric | UV Laser System A | UV Laser System B |

|---|---|---|

| Energy Cost/Month | $1,240 | $980 |

| Marking Speed | 120 units/min | 90 units/min |

| Annual Net Savings | -$2,880* | +$5,210 |

*Negative savings due to 18% throughput loss outweighing 21% energy reduction

This illustrates why 73% of factories limit speed reductions to under 20%–balancing productivity with meaningful energy savings.

About 58 percent of suppliers claim their machines have these so-called eco-mode features, but independent tests show something different. Around 41% actually turn off these modes when the machine starts up because they want maximum output. There's clearly a conflict here between getting things done quickly and being environmentally friendly. Take Yamazaki Mazak as an example though. They've developed some pretty smart technology where their fiber lasers adjust power usage based on what's needed at any given moment. The result? Machines save around 19% on energy while still managing to complete cycles about 4% faster than before. So it turns out that going green doesn't necessarily mean sacrificing speed after all.

The speed impacts energy consumption as higher speeds can increase efficiency, but reducing speeds for specific tasks, like deep engraving, can lead to higher energy use because the laser is active longer.

Technologies such as adaptive power scaling, dynamic speed modulation, and burst mode can help optimize energy use by adjusting power and speed based on real-time needs.

Fiber lasers boast better energy conversion efficiency (40-50%) due to their solid-state design, wavelength optimization, and effective pulse modulation.

AI-driven controllers use predictive analytics to adjust pulse frequency and beam focus, reducing energy spikes and optimizing efficiency in real-time.