×

×

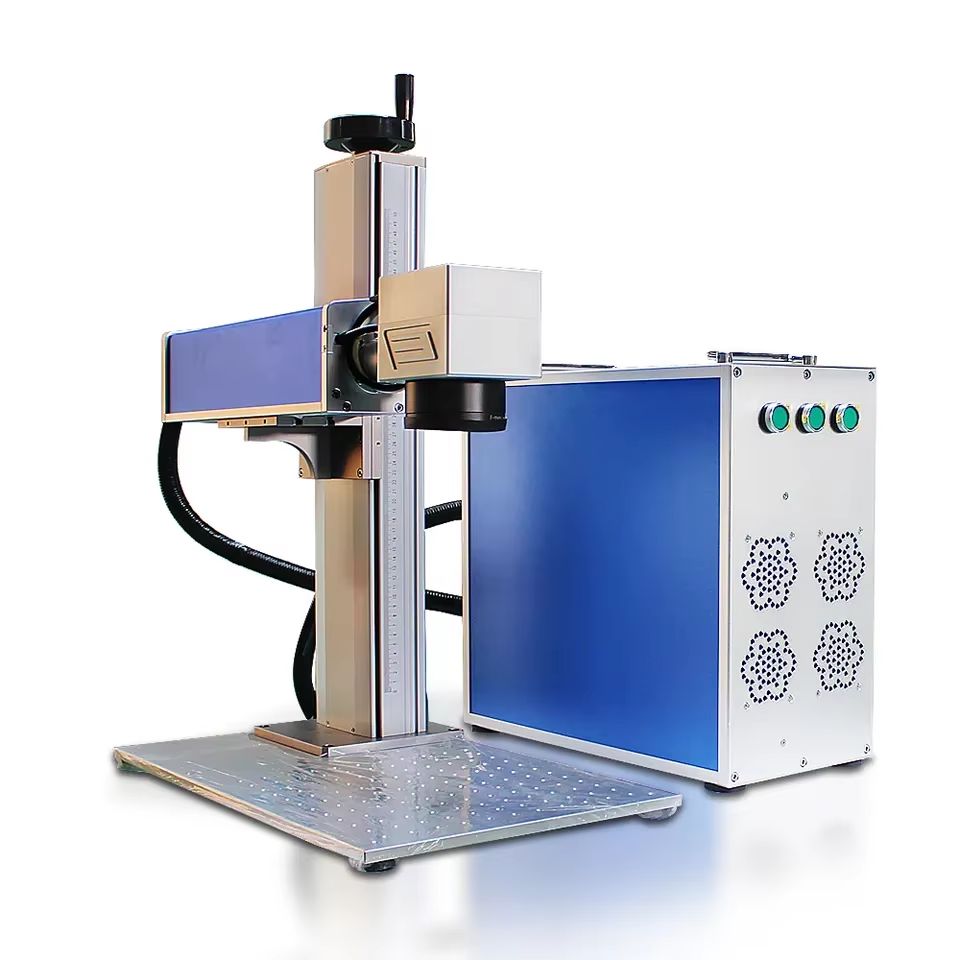

Magic Cube Laser offers expert solutions in fiber and CO2 laser marking, providing precision, durability, and versatility for various materials.

Magic Cube Laser leads in manufacturing with advanced laser technology, offering precision and efficiency in cutting, welding, and marking

Discover how Magic Cube Laser’s advanced technology ensures precise, durable, and versatile laser marking for various materials and applications.

Why Modular PCB Marking Is Essential for Agile Electronics ManufacturingModern electronics manufacturing faces mounting pressure to balance growing product complexity with compressed development cycles. Modular PCB marking systems address these chall...

How Fume Filters Protect Laser Marking Machine Components and Performance The Role of Fume Filters in Preventing Damage to Optical and Mechanical Systems Fume filters act like the initial barrier stopping airborne stuff from messing with how accura...

What Is Kerf Width and Why It Matters in Precision Cutting Machine Applications The term kerf width basically describes how much material gets cut away during machining processes, which affects both how efficiently materials are used and what size t...

The Relationship Between Marking Speed and Power Consumption in Energy Efficiency of Laser Marking Systems The connection between how fast laser markers operate and their energy needs isn't straightforward at all. When these machines first start runn...

How PCB Marking Machine Enhances Precision and Reduces Waste in Prototyping The Role of Accurate Marking in Minimizing Rework and Material Waste PCB marking machines today cut down on prototype waste somewhere between 18 to 34 percent when compared...

Discover core maintenance practices for precision cutting machines. Learn about daily cleaning, monthly inspections, belt and blade replacements, precision calibration, and safety protocols to ensure longevity and optimal performance for your cutting machinery.